What is it?

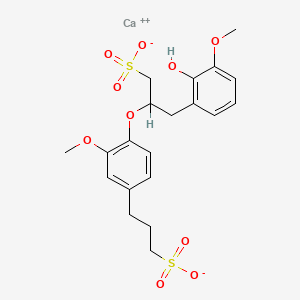

Calcium Lignosulphonate is an amorphous material originating from lignin, a light-yellow-brown power which is soluble in water, but not in organic solvents. The compound is extracted from sulfite pulping of softwood with the framework consisting of three aromatic alcohols: coniferyl, alcohol, p-coumaryl alcohol, and sinapyl alcohol. The principal unit is coniferyl alcohol. Commercially, Calcium Lignosulphonate is available as sodium and calcium salts which have been used in a wide range of applications. Resulting from their dispersing, binding, complexing, and emulsifying properties.

Manufacture processes

- Calcium Lignosulphonate is created from softwood in the sulfite pulping method for paper manufacturing. The wood chips are let digested in acidic calcium bisulfite solution in large reaction vessels while being processed through a cooking cycle of 6 to 10 hours. 130 degree Celsius or approximately that number is the highest cooking temperature during the process. Within the process, bisulfite ions will react with the native lignin polymer of the wood to form sulfonated lignin.

- This reaction helps increase the water-solubility of the hydrophobic lignin polymer, and the calcium bisulfite provides the calcium ions that stabilise the anionic sulfonate groups in the lignosulfonates.

- After completing pulping, water-insoluble cellulose and soluble calcium lignosulfonate are separately filtered.

- The brownish filtrated, containing the lignosulfonates, will also contain residual amounts of sulfite salts and reducing-sugar monomers formed from wood cellulose during pulping. Then, the pH of the filtrate is controlled by adding concentrated sulfuric acid. The water and sulfite (as sulfur dioxide) content are reduced by subsequent evaporation.

- After the first evaporation step, the filtrate is water-diluted before being subjected to further purification by ultrafiltration at moderately elevated temperatures. Ultrafiltration is a liquid/liquid separation method as the filtrate is separated by molecular size through a semipermeable membrane. The ultrafiltration step will separate the high-molecular-weight lignosulfonate fraction from depolymerisation products, for instance, low-molecular-weight lignosulfonates, and reducing-sugar monomers. Additionally, the use of other than softwood as a source material would not yield a product with the desirable high-molecular weight distribution.

- The purified calcium lignosulfonate (40-65) from ultrafiltration may be pH-adjusted by the addition of dilute sulfuric acid. The solution will be evaporated afterwards at a temperature from 95-105° to a dry-matter content that is suitable for spray-drying. The outcome is spray-dried to moisture content following the specification for Loss on drying and filled into containers suitable for holding food.

Applications

- Could work as a plasticizer in making concrete to maintain the ability of concrete to flow with less water. Also used during the production of cement, where they act as grinding aids in the cement mill and as a raw mix slurry deflocculant.

- Could be used in lead batteries to act on the crystallisation of the lead sulphate thus increasing the battery to get a much longer lifetime.

- Could be used as a filler and binder in ceramic tiles, resins to fibre boards, casting sand and in fodder pellets.

- Work as dust-suppression roads as well as in dusty processes within the industry. Lignosulfonate is used as a dispersant in products like fodder, dispersed pesticides, dyes, carbon black, and other insoluble solids and liquids in water.